Rigid Reel-Lay Pipe-in-Pipe Installed Offshore Malaysia

McDermott International, Inc. reports that its subsidiary has become the first to install rigid reel-lay pipe-in-pipe in Asia-Pacific for the Siakap North-Petai (SNP) development project offshore Malaysia. At more than 3,900 feet (1,190 meters), the SNP development is one of the industry’s most challenging deepwater projects.

“Successfully installing the rigid reeled pipe-in-pipe flowlines on the Siakap project is a significant achievement for McDermott and a first for the region,” said David Dickson, President and Chief Executive Officer, McDermott. “It’s testament to the expertise of our people, the performance of our vessels and our capability to deliver complex deepwater projects. The performance of our project team and vessels in the final months of installation was critical in helping our client achieve first oil at the end of February.”

McDermott was awarded the full turnkey contract in December 2011 for the project’s subsea infrastructure. This includes the design, procurement, fabrication and installation of two complex rigid insulated pipe-in-pipe production flowlines, one rigid water injection and one main umbilical system connecting eight new manifolds and subsea distribution units to existing riser slots. As part of the pipe-in-pipe and water injection flowline system, McDermott combined its design capability from both its Houston and Singapore Subsea engineering offices, completed all spooling activities at its in-house regional spool base and fabricated the Pipeline End Termination (PLET) and In Line Tee (ILT) structures.

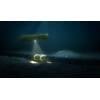

Installation of the pipe-in-pipe production flowlines and rigid water injection flowlines was undertaken by McDermott’s Lay Vessel North Ocean 105, while flexible risers were installed by McDermott’s North Ocean 102.

Lay Vessel North Ocean 105 is a dynamically positioned, fast-transit vessel, with advanced reel-lay systems for rigid and flexible pipelay in water depths up to 10,000 feet. It can install a variety of pipelines, umbilicals, subsea hardware and deepwater moorings for floating facilities. LV105 has a 44-ST (400-MT) top tension laying capacity and a 2,750-ST (2,500-MT) rigid pipe payload. It is equipped with a PLET handling system which allows for safe handling of PLET and ILT structures as they are integrated into the pipelines during the installation.

North Ocean 102 is a fast-transit, dynamically positioned vessel with a high top tension Vertical Lay System for Subsea needs that operates across a wide variety of water depths.

mcdermott.com

December 2024

December 2024