Kraken Oil Project Gets Custom Subsea Spreaders

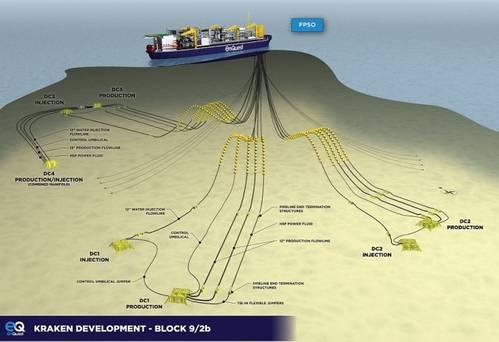

Heavy lifting equipment and engineering specialist Modulift announced it has manufactured two custom subsea spreader beams for the subsea construction company currently conducting a large-scale engineering, procurement, installation and construction contract for EnQuest’s Kraken development, one of the largest subsea heavy-oil field projects under development in the U.K. sector of the North Sea.

The below-the-hook equipment manufacturer delivered the 303t capacity, 6.8m span spreaders to its customer on site, where the scope of work includes template and manifold installation at three drill centers.

Modulift’s spreaders will be used to lift the manifolds into position on stage one of the project, before going into storage for six to 12 months prior to reuse on later stages.

Liam Botting, new business development manager at Modulift, said, “This is a landmark project on which to showcase the engineering behind our new range of spreaders for subsea use. The range incorporates our drop link design to ensure the beam doesn’t have any bending force through it—other than due to self-weight—thus reducing the overall size and weight of the beam, creating a more efficient design.”

Botting added that the design features an open section to ensure that there are no issues with pressure equalization, and that all surfaces can be covered with a high build epoxy paint suitable for subsea environments.

Before delivery, each item of equipment used on the Kraken development was required to be sent to DNV GL for inspection.

Modulift timed the launch of its new subsea modular spreader beams to follow publication of a revised offshore standard from DNV—titled DNV-OS-H206—that references the use of spreader bars. The manufacturer took the concept behind the unique modular elements of its standard and heavy spreader beam ranges to product a versatile and efficient collection for deep water lifting, features demonstrated in the custom subsea spreader beams for the Kraken development.

December 2024

December 2024